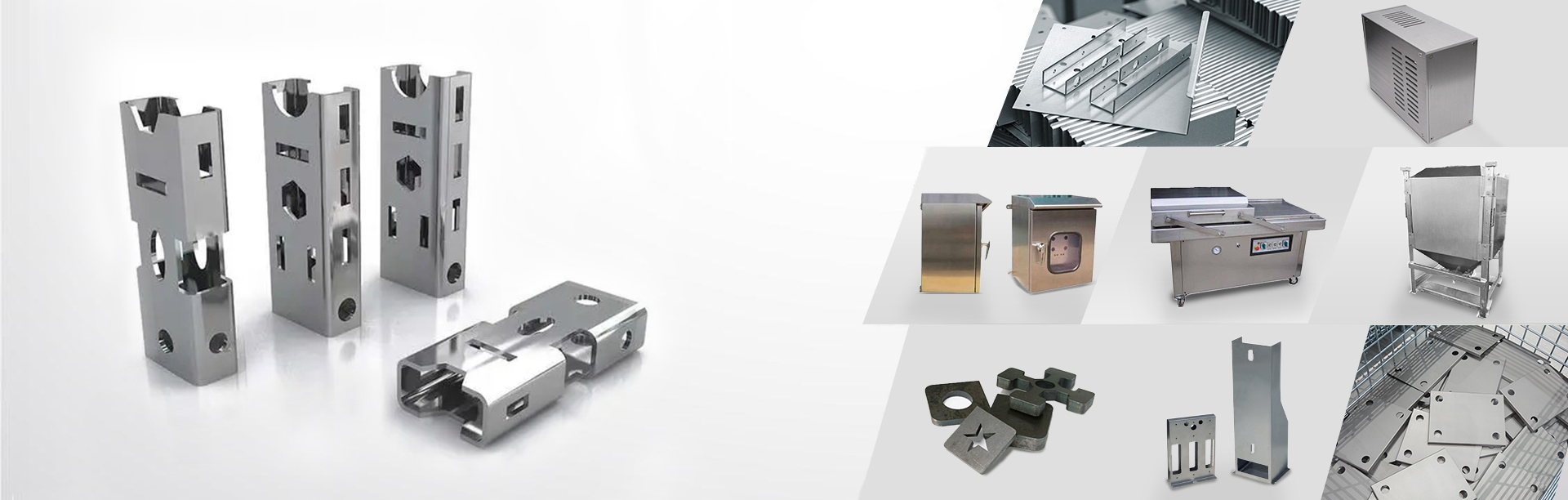

1. Main materials: high-quality stainless steel plate, high-quality galvanized plate, high-quality carbon steel plate, high-quality aluminum alloy, etc.

2. Plate thickness: 0-20mm

3. Machining accuracy: + / - 0.1mm

Recommend to you

Detailed information

Product introduction:

1. Main materials: high-quality stainless steel plate, high-quality galvanized plate, high-quality carbon steel plate, high-quality aluminum alloy, etc.

2. Plate thickness: 0-20mm

3. Machining accuracy: + / - 0.1mm

The detailed information:

Laser processing is to use the energy of light after the focus of the lens to achieve a high energy density, processing by photothermal effect. Laser processing does not need tools, fast processing speed, small surface deformation, processing of various materials. Laser beam is used to process materials, such as drilling, cutting, slicing, welding, heat treatment and so on. Some substances with metastable energy level will absorb light energy under the excitation of external photons, so that the number of atoms in the high energy level is greater than the number of atoms in the low energy level -- particle number inversion. If there is a beam of light irradiation, the photon energy is equal to the difference between the two energies, then stimulated radiation will be generated, and a large amount of light energy will be output.

1, the laser power density is large, the temperature of the workpiece after absorbing the laser rapidly increases and melts or vaporizes, even if the melting point is high, hardness and brittle material (such as ceramics, diamonds, etc.) can also be used for laser processing;

2. The laser head is not in contact with the workpiece, and there is no wear problem of the workpiece;

3, the workpiece is not subject to stress, not easy to pollution;

4, can be the movement of the workpiece or sealed in the glass shell material processing;

5, laser beam divergence Angle can be less than 1 milliarc, spot diameter can be small to the micron level, the action time can be short to nanosecond and picosecond, at the same time, the continuous output power of high-power laser can be kilowatts to the kilowatts level, so the laser is suitable for precision micro machining, and suitable for large material processing;

6, laser beam easy to control, easy to be combined with precision machinery, precision measurement technology and electronic computer, to achieve a high degree of automation and machining precision;

7. Laser processing can be carried out by robots in harsh environments or inaccessible places.

In the process of laser cutting, the cloth will not deform or wrinkle, the laser cutting size precision is high, the laser cutting shape can be arbitrarily changed with the drawing, increasing the practicality and creativity of the design. In addition, laser cutting technology is to use "laser knife" instead of metal knife, laser cutting any fabric, can instantly melt and solidify the incision, small gap, high precision to achieve the function of automatic "locking".